Renewability

The principal raw material for NatureFlex™ and Cellophane™ is cellulose, a renewable raw material from trees. The wood pulp contained in our cellulose products originates from certified forests in line with our Wood Pulp Sourcing Policy, which describes our commitment to ensuring that we uphold the principles and standards laid down by the two main international forestry certification schemes: the FSCTM (Forest Stewardship CouncilTM) and PEFC (Programme for the Endorsement of Forest Certification). The pulp is sourced from trees grown in conditions which do not require additional irrigation. The use of herbicides, insecticides and fertilisers is low to minimise the environmental impacts of this process.

Our US and European operations hold both FSCTM and PEFC Chain of Custody certification.

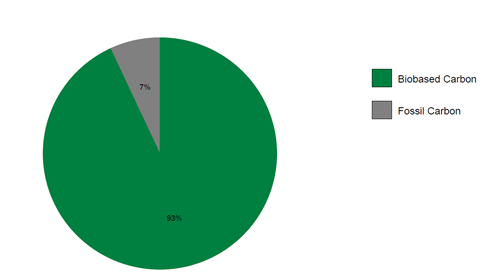

Our films have been tested to ASTM D6866, which determines the amount of bio-based carbon, by measuring the ratio of ‘new carbon’ to ‘fossil carbon’ sources.

Standard uncoated and coated cellulose films generally contain between 90 and 99% renewable raw materials (RRM).

Source: Beta Labs 14C test on NatureFlex™ 30NVR film

Test Method: ASTM D6866

Further information on individual grades is available from the Futamura Marketing Department.

The USDA has a Bio-preferred Programme, which has a number of different product categories with different minimum biobased content requirements. For packaging applications a minimum content of 30% is required.

NatureFlex NPU, NK, NKA, NKR, NVS, NVR, DNE and NE are currently eligible to carry the USDA logo.